Navy Vet Joins Water Authority as SkillBridge Program Intern

The San Diego County Water Authority’s new SkillBridge Program intern came ashore in the perfect location. Of all the adventures Trevor Bland’s military service has taken him on, he regards San Diego as his favorite. It is here where he enjoys physical fitness, trips to the beach and the city’s Mexican food scene.

Luckily, when Bland joined the Department of Defense SkillBridge program he didn’t have to go far.

Bland was assigned as a human resources analyst intern with the Water Authority in August after five years of Naval service. Drawing from his experience as a U.S. Navy Surface Warfare Officer, he says, gave him the skills to address personnel issues in the civilian workforce.

Navy experience benefits SkillBridge Program intern

“My time in the Navy taught me how to stay calm, think clearly and problem solve in high pressure situations,” Bland said. “This experience with problem mitigation and solutions prepared me for the many roles in the human resources department.”

After receiving his B.A. in Psychology from Suffolk University in 2019, Bland commissioned in the U.S. Navy. Inspired by his father’s service of more than 30 years, he says the path to service always felt natural.

Bland began his first naval tour aboard the USS Dewey in San Diego, where he served as a Repair Officer and Boarding Officer.

In August of 2021 when the USS Dewey’s homeport was transferred nearly 6,000 miles away to Yokosuka, Japan, Bland followed.

During this 12-month stay in the South China Sea, Bland led a team of 10 specially trained sailors in counter-piracy missions that tackled smuggling and theft.

Bland finished his military career in late 2022 with his second and final tour as the Auxiliaries Officer and Assistant Chief Engineer on board the USS Harpers Ferry.

“My time in the Navy taught me how to stay calm, think clearly and problem solve in high pressure situations,” Trevor Bland said. “This experience with problem mitigation and solutions prepared me for the many roles in the human resources department.” Photo: San Diego County Water Authority

SkillBridge Program intern gains new experience

Now at the Water Authority, Bland’s role includes promoting job openings, ensuring consistency among various HR projects and assisting other outgoing military personnel with their career changes.

Transitioning from active duty to civilian life can be intimidating, says Bland. Without a clear vision for one’s career path and daily life, many members leave the service fearful for the future.

“For the first time in however many years, the service member is alone in ensuring everything from their medical insurance to financial stability is in order, when prior to that, those benefits were awarded to them,” Bland said.

It’s at this pivot point where SkillBridge makes the difference. SkillBridge offers service members a chance to gain new experience and skills in the civilian workforce before they leave the military.

Upon joining the four-month program, members receive the same military benefits and pay they received on active duty while working full-time in a civilian field of their choice.

“When you’re in SkillBridge, you still have the security of your military career while experimenting with different jobs,” Bland said.

New perspectives for employers

Participation in the program not only helps service members, but it’s rewarding for employers as well. Employers gain early access to the new perspectives, diverse and dedicated skills that SkillBridge interns bring from years in the military.

“Interns like Trevor are a great addition to our department because they bring skills and a proven work ethic from the military that would otherwise be untapped if not for SkillBridge,” said Gretchen Spaniol, Water Authority acting director of human resources.

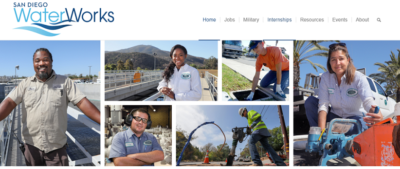

As the first public agency in California to partake in the Department of Defense’s Skillbridge Program, the Water Authority has led the way in integrating former military personnel into the water industry. Since joining the program in 2020, the Water Authority has welcomed eight military interns.

For the interns, the payoff is clear. “The cooperation and support provided by the Water Authority make this life change a lot less scary,” Bland said.

As the home to both Navy and Marine Corps families, San Diego has more than 110,000 active-duty personnel, with military families constituting nearly 8% of the county’s population. Of the more than 30,000 service members departing from the military each year in California, over half reside in the San Diego region.

The Water Authority’s successful participation in SkillBridge highlights the agency’s commitment to military personnel and families.