Escondido Employee Named California Laboratory Person of the Year

City of Escondido Water Quality Lab Associate Chemist Oyuna Jenkins has been named “Laboratory Person of the Year” by the California Water Environment Association for 2019-20.

Supervising Chemist Ralph Ginese nominated Jenkins for the award, calling her “an incredible asset” during her seven years working at the lab. “The lab technically could not function without Oyuna,” wrote Ginese.

“This is really teamwork,” said Oyuna Jenkins of her recognition. “I have to give credit to everyone in the lab. We work really hard. Whoever you call a hero, there are always people behind them.

“It’s all about public health. I feel like it’s making a difference, providing accurate information to the public as possible. It’s all coordination between distribution, collection, public works, and everyone involved.”

Escondido lab helps ensure safe, reliable water supply

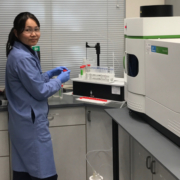

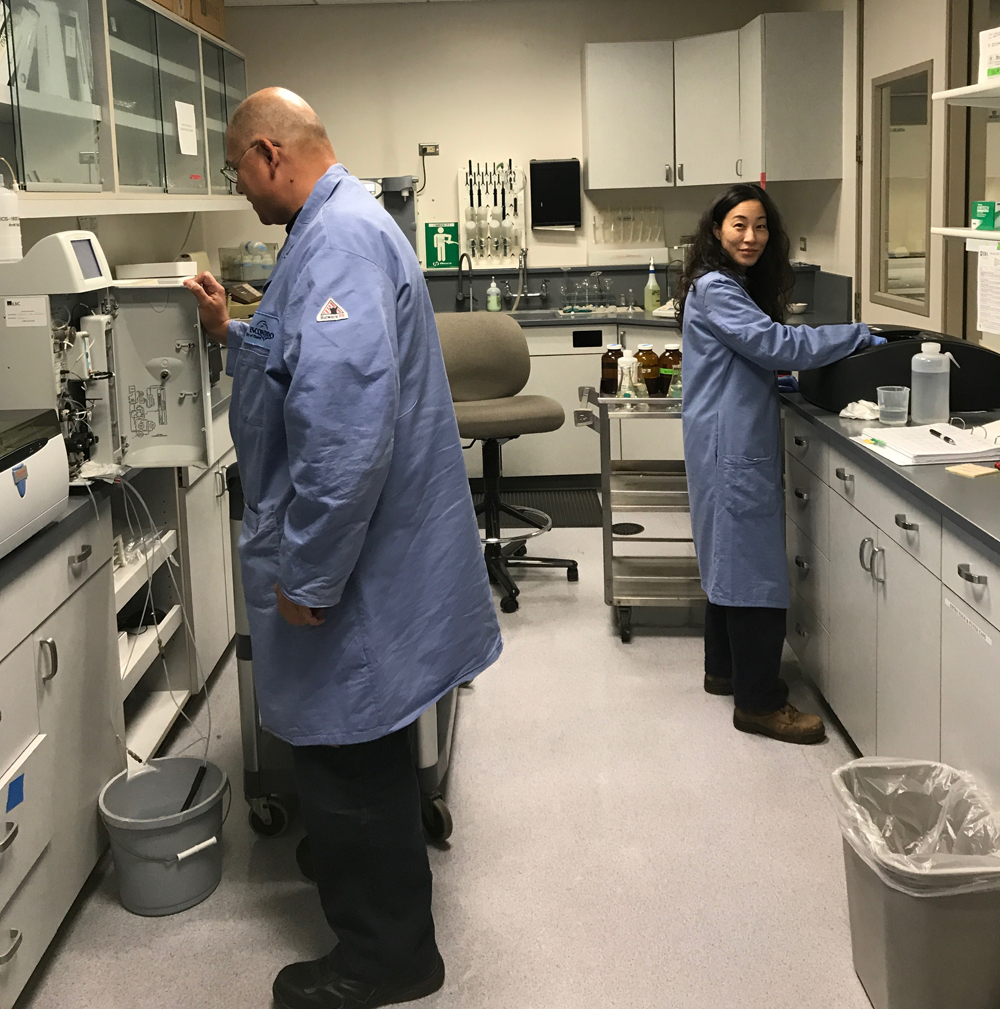

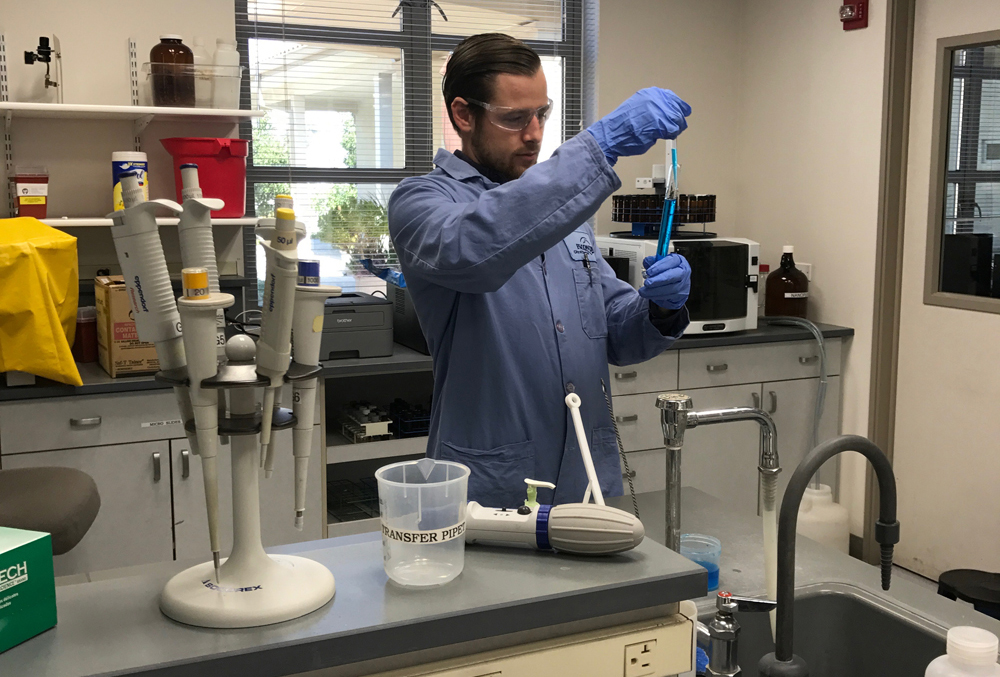

Jenkins plays a key role in the lab’s safety processes, which ensures a safe, reliable water supply for City of Escondido customers. She runs metal analyses on drinking water, industrial waste, and every step of the wastewater treatment process. Jenkins also peforms required monthly and quarterly testing and cross-trains colleagues on testing procedures. In addition, she is the laboratory’s liaison to contract labs.

“She’s very analytical,” said Ginese. “She’s someone we can go to, brainstorm, and work together. She is not afraid when people question her data. She is secure in what she does.”

Escondido lab plays leadership role in advanced water quality testing

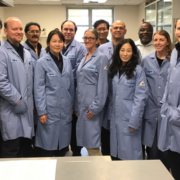

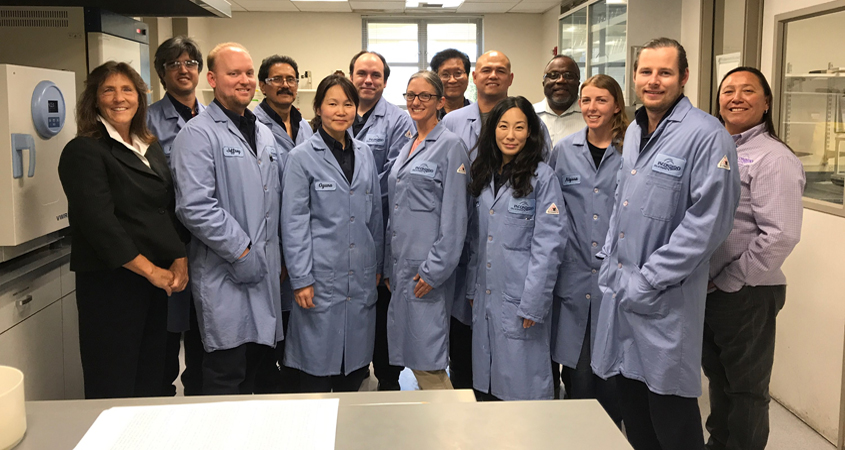

Oyuna Jenkins (fifth from left) and the 14 person Escondido Water Quality Lab team, one of only two certified labs in California under new water quality standards. Photo: City of Escondido

From Mongolia to Escondido

A native of Mongolia, Oyuna Jenkins earned her bachelor’s degree in chemistry from the Mongolian University of Science and Technology, which is among the top 15% of all programs worldwide. She immigrated to the United States in 1998. Jenkins continues to pursue advanced training. She first obtained CWEA certification in 2012 and completed the Water and Wastewater Certification program at Palomar College in 2016.

“Oyuna has worked tremendously hard to be where she is at today,” wrote Ginese in his award nomination. “She is grateful for the opportunity this country gives her and she shares that gratitude with those around her … She is what every supervisor/manager is looking for in a Laboratory Person of the Year Award.”

Escondido Water Quality Lab leads the way

Jenkins helped develop strategies to implement new techniques and processes supporting the implementation of strict new accreditation standards for California’s 600 certified water quality testing labs.

As reported earlier this year on Water News Network, the City of Escondido Water Quality Lab successfully adopted the anticipated regulations in advance of their formal implementation. Jenkins reviewed and wrote many of the lab’s new Standard Operating Procedures now being used. She also assisted in developing the facility’s annual goals, along with its new mission and value statements.

The ambitious approach to Environmental Lab Accreditation Program compliance under the more stringent quality control processes places Escondido in a leadership role as one of only two California labs already compliant with the new regulations.