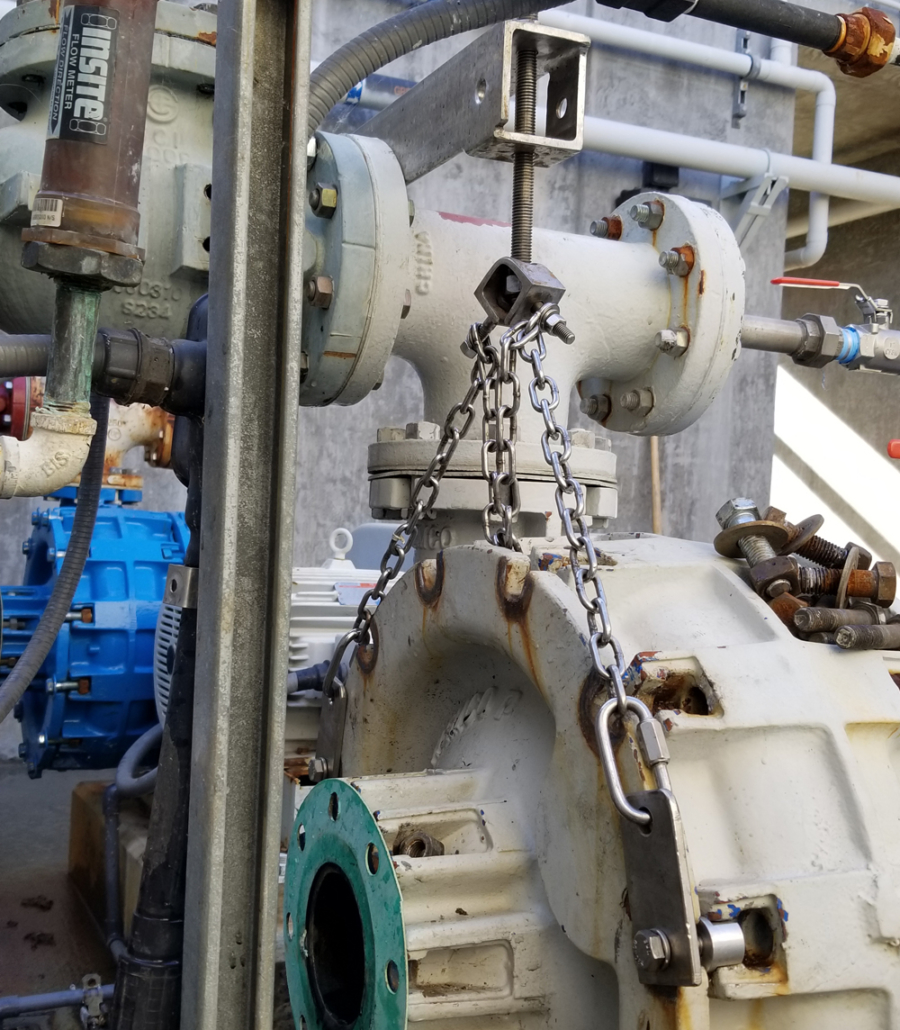

Escondido Plant Maintenance Technician Joseph Lucero won third place in the 2019 California Water Environmental Association Awards for his safety device. Photo: Courtesy John Del Fante, CIty of Escondido

Escondido Plant Maintenance Technician Joseph Lucero won third place in the 2019 California Water Environmental Association Awards for his safety device. Photo: Courtesy John Del Fante, CIty of EscondidoInnovation Improves Safety, Wins Award for Escondido Wastewater Technician

An Escondido water employee’s ingenuity improved safety at a city treatment plant and won a statewide water industry award.

City of Escondido Plant Maintenance Technician Joseph Lucero won third place in the “Gimmicks/Gadgets” category in the 2019 California Water Environmental Association Awards competition. His innovative safety device turns a difficult two-person job working on wastewater pumps into a safer process one person can complete alone.

Lucero, a 20-year veteran in the water and wastewater industry, recently transferred to his current assignment at the city’s Hale Avenue Resource Recovery Facility (HARRF), a secondary treatment facility which can treat a flow of 18 million gallons per day for the City of Escondido and the Rancho Bernardo area of San Diego.

“When I transferred and started working on the grit pumps, I understood why it was among the least favorite jobs to do,” said Lucero.

Brainstorming creates innovative approach

The bulky cover originally required two men in tight quarters to move safety. Lucero’s device allows it to be removed and replaced safely by one person. Photo: Courtesy John Del Fante, CIty of Escondido

Workers found it difficult to maneuver the heavy, bulky cover over the rotor assembly of the pump. Two people were needed to muscle the cover in tight quarters, and it carried a risk of back strain.

Lucero says he started to brainstorm, tapping his water industry experience.

“I was determined to come up with a device or a technique to eliminate the back fatigue, reduce time, and increase safety,” he said.

Without an existing device or specialty tool available to perform necessary maintenance or repairs, it meant Lucero had to design and fabricate something brand new.

Team effort results in improved safety

Lucero worked on the project during his off-hours.

He first designed the cover device on paper from an original concept, and then made a cardboard sample to produce a mock-up he could work with for placement, fit, and accuracy. A prototype was created which consisted of a bracket, a height adjustment all thread, chain sling device, and the pump cover attachment plates.

After testing the design, Lucero says he received key help from Raul Adame, a Plant Systems Technician at HARRF. Adame fabricated alignment tabs at his machine shop at home to help improve the device.

Lucero always believed in his innovative tool, but said it worked even better than he expected.

New device saves time and costs

“It was an immediate hit with those that work on the grit pumps,” Lucero said. “It saves time, money, and more importantly creates a safer work environment.”

Lucero’s innovative creation is used by all personnel when performing predicative maintenance and repairs on the grit pumps.

“The device turned a two-person job into a one-person job,” said John Del Fante, operations superintendent at the facility. “This device allows an individual to support the full weight of the pump cover, clean the interior easily, and reinstall. It used to take two people to muscle this piece in and out of place.”

For Lucero, winning his award for innovation was an unexpected and welcome surprise.

Plant System Technician Jason Blacksher, a co-worker Lucero calls “my biggest supporter in designing the device,” submitted the CWEA award nomination.

“We are going through a safety culture change at HARRF and it’s working,” said Lucero. “I am surrounded by talented, knowledgeable and innovative co-workers. I learn from them every day as we grow as a team on the path to a safety conscious and innovative culture.”