Fresh water aboard Midway was critical to building up enough fresh-water steam to accelerate this A-6E Intruder from 0 to approximately 150 miles per hour in only three seconds. Photo: USS Midway Museum

Fresh water aboard Midway was critical to building up enough fresh-water steam to accelerate this A-6E Intruder from 0 to approximately 150 miles per hour in only three seconds. Photo: USS Midway MuseumUSS Midway: A History of Sustainable Water Management

The USS Midway Museum, docked in San Diego, is the most popular naval warship museum in the United States and among the most visited museums in the country, with 1.4 million people annually coming aboard.

Those visitors discover the Midway made its own fresh water while at sea, from the first day it was commissioned in 1945 until it was taken out of active service in 1992. But when this venerable aircraft carrier found new life as the USS Midway Museum in 2004, its relationship with water entered a new era as well.

The USS Midway Museum served as host for the launch of the San Diego County Water Authority’s new education and outreach program: Brought to You by Water.

The program underscores the importance of water reliability for the region’s key industries such as tourism and the military — something the operators of the USS Midway Museum understand on multiple levels.

Supporting a floating city at sea with water supplies

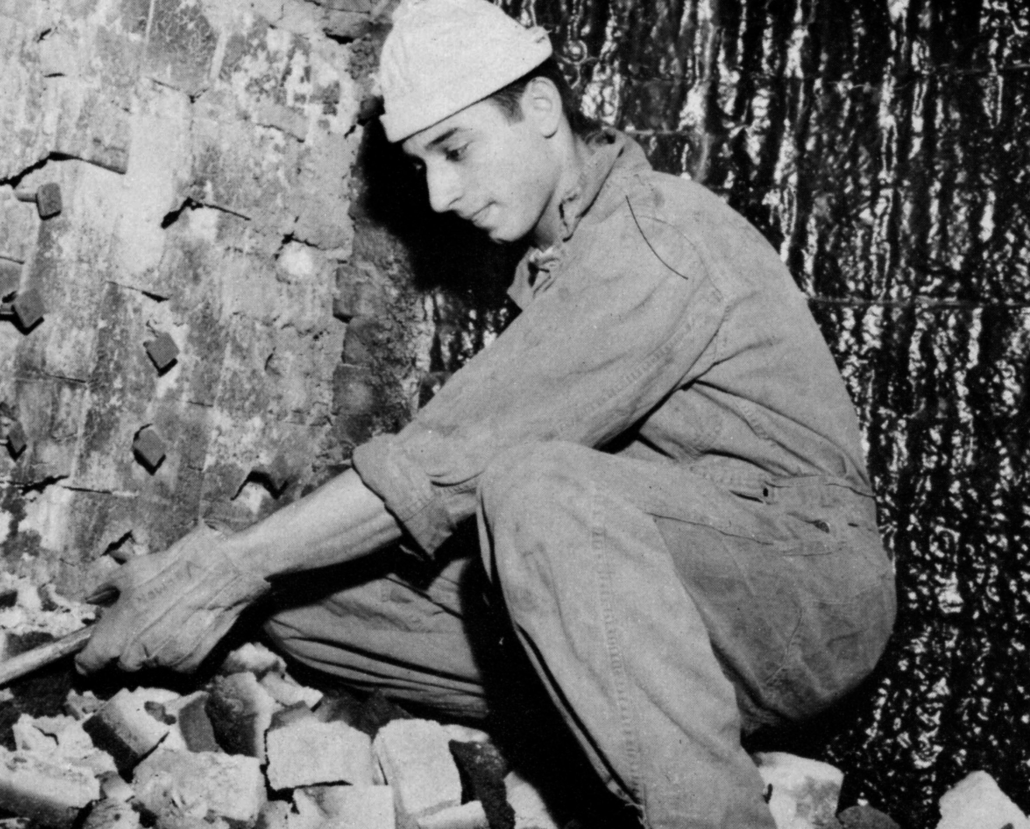

Twelve massive boilers aboard Midway converted fresh water into steam, the lifeblood of any aircraft carrier. Those boilers required periodic scraping, a dirty job far below the water line. Photo: Courtesy USS Midway Museum

When deployed at sea, sailors aboard the USS Midway produced 240,000 gallons of fresh water daily through 12 boilers to support the floating city of 4,500 men. From cooking pasta to feeding sailors, to propelling the catapult system launching aircraft off the flight deck, the Midway depended on a safe and reliable water supply to thrive, just as the San Diego region does today.

Two evaporator plants deep inside the ship took in seawater and produced fresh water via desalination. According to Scott McGaugh, Midway Director of Marketing, working in those “evap spaces” was among the toughest duty assignments aboard the Midway. When one of these plants went out of service, the Midway had to ration its water.

Even in the best of times at sea, sailors always lived with a limited water supply, and water conservation was standard operating procedure. Consider a “Navy shower” — getting wet for 30 seconds or less, shutting the water off, soaping up, and then a quick rinse. That was the lifestyle during deployment, including a stretch when the Midway set a deployment record for aircraft carriers — 327 consecutive days at sea.

Water conservation remains a priority

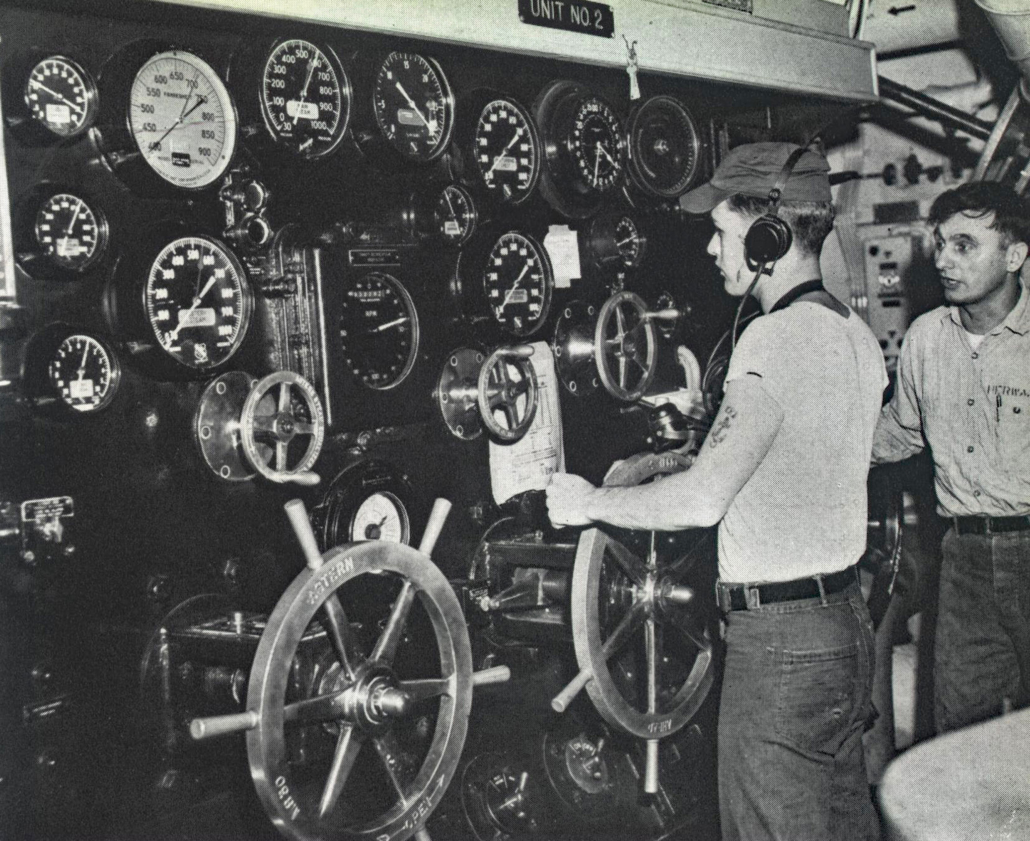

Four steam throttle boards such as this were the gas pedals aboard Midway. Sailors here in 1958 fed the proper amount of steam into the four turbines necessary for propulsion and a top reported speed of 30 knots per hour. That’s 34 miles an hour for the 65,000-ton aircraft carrier when active—fast enough to water ski behind Midway. Photo: Courtesy USS Midway Museum

While the USS Midway Museum doesn’t have to generate its own fresh water anymore, the conservation mindset is still a part of its daily life. Chief Engineer Len Santiago for the Midway says it is a priority for his team of 64 engineers to be good stewards of water and the ship deploys modern technology such as waterless urinals and sensors on faucets.

The most critical issue for the USS Midway Museum is water leaks. The Water Authority encourages homeowners to monitor their plumbing for leaks. Now imagine monitoring hundreds of miles of pipes aboard a floating museum.

“My staff and I have to make sure first, no leaks,” said Santiago. His team checks all systems regularly. “We have hundreds of spaces where pipes run through. We check all sensors in our restrooms for guests are working properly. Problems like a running faucet are reported immediately.

“As we grow as a museum, our infrastructure will continue to grow,” said Santiago. “In the 21st century, we’ll continue to leverage technology. I expect to have sensors that will alert me to water on the deck somewhere that might indicate a leak – even in things like air conditioning.”