Escondido Water Quality Lab Leads By Example

California’s 600 certified water quality testing labs will face strict new accreditation standards in the near future. While final hearings still need to take place on the draft regulations before adoption, the City of Escondido Water Quality Lab isn’t waiting. Escondido is working now to adopt the anticipated regulations.

Escondido is one of only two California labs already compliant with the draft regulations, which require more stringent quality controls.

The laboratory is certified by the California State Water Resources Control Board’s Environmental Laboratory Accreditation Program to conduct 155 different certified test methods to ensure Escondido water and wastewater safety, including reclaimed water samples, stormwater samples, drinking water samples, wastewater from various stages throughout the treatment process, and industrial wastewater collected from permitted industries.

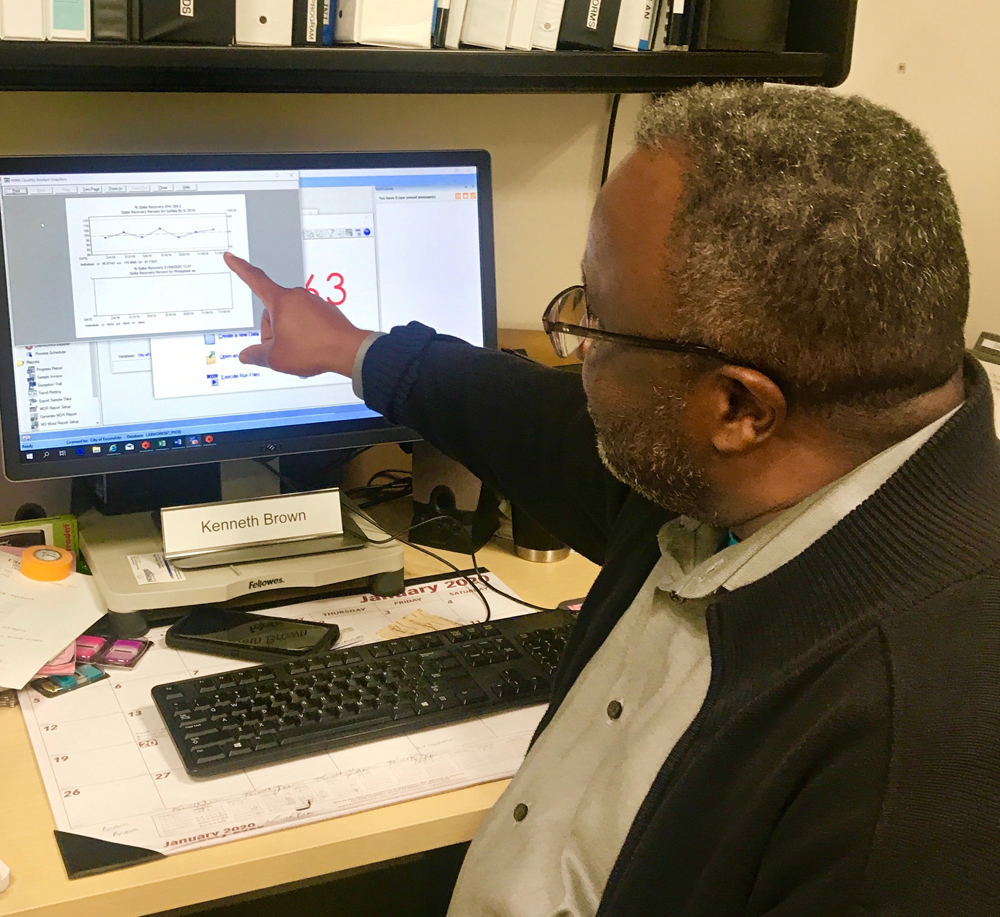

As part of compliance with the new standards, Laboratory Technician Ken Brown was promoted to the lab’s Quality Assurance Officer. Photo: City of Escondido

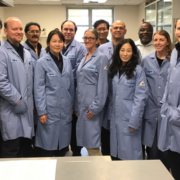

City of Escondido Laboratory Superintendent Nicki Branch supervises the 13-person lab staff. She said the decision was made to work toward Environmental Lab Accreditation Program compliance right away rather than wait for formal implementation.

“We thought, this regulation is coming,” said Branch. “It’s going to be the law. Let’s just go ahead and comply with it now. Each water quality laboratory has to be certified by the state. Adding the [proposed] standards adds more quality assurance and quality control procedures for everything you do in the lab.”

Improved reporting of water quality testing

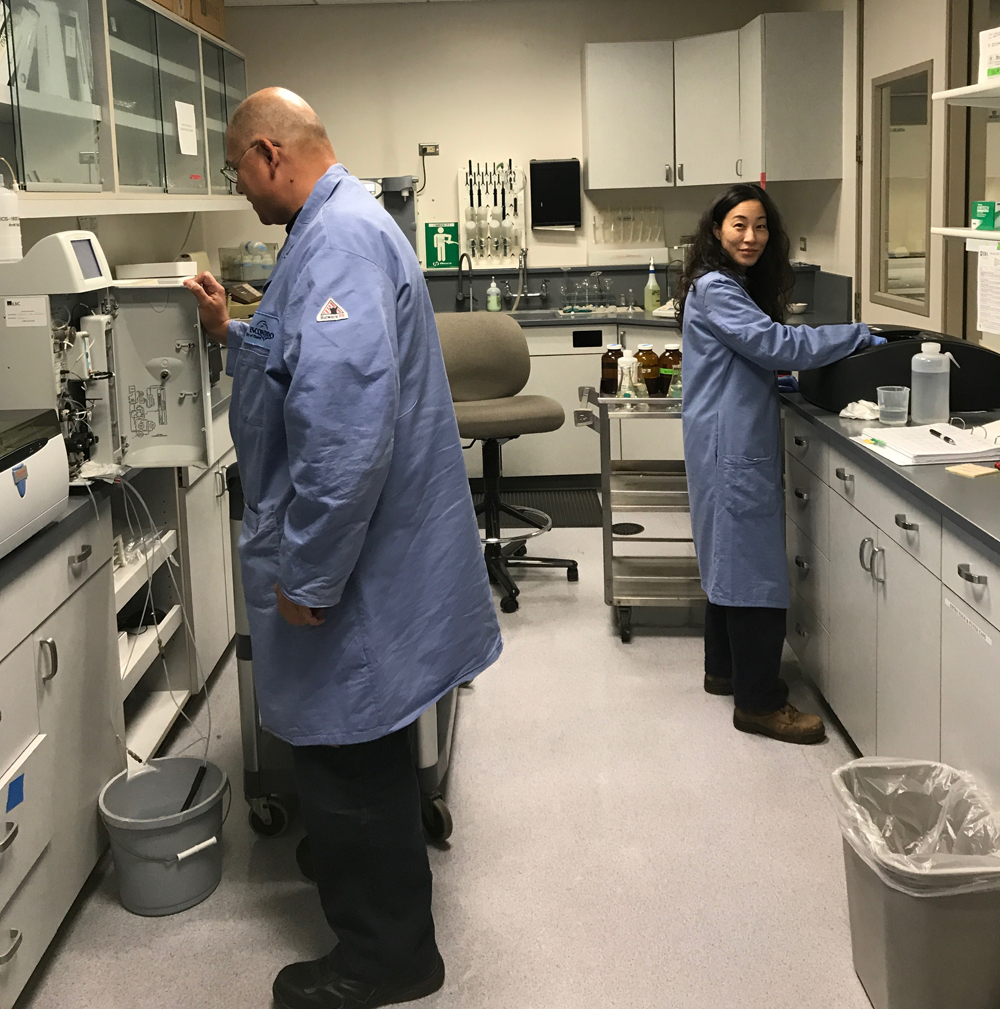

Damien Wong (left) and Michelle Sohn at work in the Escondido Water Quality Lab. Photo: City of Escondido

Branch said the standards implement more rigorous reporting, not new processes.

“It takes what we are doing now and makes the data more defensible,” she said. “We can show the chain of custody and verify our procedures, from sampling to analyzing to reporting. The process protects the integrity of the data.”

The proposed new requirements are based on 2016 standards developed by The NELAC Institute, a nonprofit organization dedicated to promoting “the generation of environmental data of known and documented quality through an open, inclusive, and transparent process that is responsive to the needs of the community.”

Escondido staff share expertise with industry peers

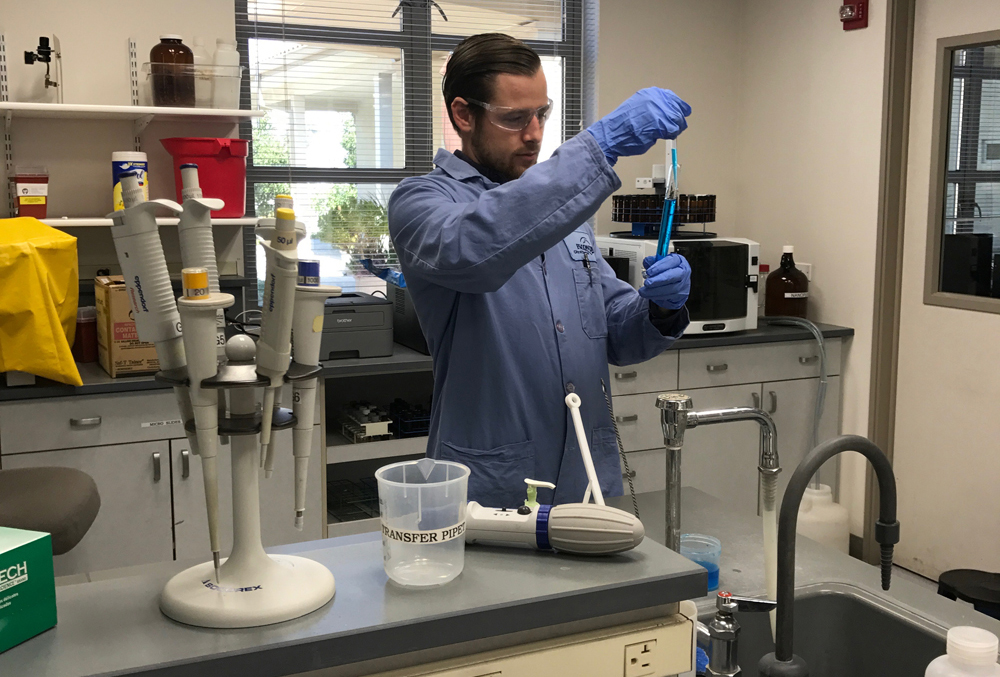

Brett Kelley conducts a test in the City of Escondido Water Quality Lab. Photo: City of Escondido

Branch said it took a full year to implement the additional sampling and paperwork. Once the City of Escondido completed the process, she realized her team gained valuable insight other labs would need. She encouraged her staff to submit abstracts to speak on the proposed new regulations at the annual 2019 California Water Environment Association conference.

“We had five people speaking who had never made a presentation before,” said Branch. “I told them ‘You are now the experts.’”

Lab staff presentation at 2019 CWEA Tri-State Seminar

“We expect to give more presentations this year,” said Branch. “Labs will need to do this. We can help people, counsel them, and give them tips. People are apprehensive. It’s human nature. ‘No, not more regulation!’ But when you are a lab doing drinking water analysis, you want the lab to be that stringent and that accurate with quality assurance procedures.”

Personal pride in the achievement, improved teamwork, and sharing their new knowledge as subject matter experts were unexpected benefits.