Drones Offer Water Agencies Cost, Safety Benefits

Water agencies across San Diego County are saving time and money while improving employee safety with drones.

Industry analysts say drone use by water agencies worldwide is growing. The Helix Water District, Otay Water District and the San Diego County Water Authority have embraced the technology, using drones to inspect and monitor facilities, and to map and survey inaccessible areas.

Helix used a drone in February to check rooftop air vents on a water storage tank in El Cajon, rather than send employees high in the sky to do it. The agency determined it was too risky for employees – even with safety equipment – and too costly to have staff inspect the vents outside the 120-foot-high Fletcher Hills Combined Tank.

“We continually look for ways to utilize technologies where appropriate to minimize facility down time and to keep staff safe,” said Carlos Lugo, general manager at Helix. “Drone technology is proving to be a useful and cost-efficient way to survey and keep the district’s facilities properly maintained.”

Drones provide a safe and cost-effective alternative for inspecting the condition of storage tank vents without placing employees at risk or taking the storage tank offline. Photo: Helix Water District

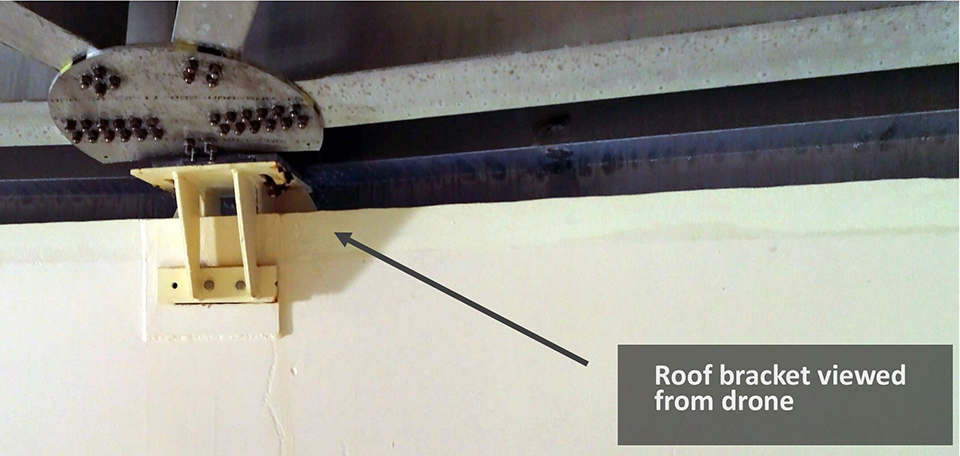

Helix uses drones to inspect interior roof supports of its water storage tanks. The supports are especially vulnerable to corrosion because they are constantly exposed to humidity and heat.

Drone image of a roof bracket inspection. Photo: Helix Water District

Inspecting the storage tank roof supports requires moving 30-foot-high scaffolding from one support to the next, a time-consuming and labor-intensive process. To cut down that time, Helix used a drone to get high-resolution images of the supports. The drone images showed which ones needed repair without moving the scaffolding to each support.

A drone helps reduce the need to move scaffolding to each bracket during inspections. Photo: Helix Water District

“Using drones for this type of inspection work is a simple, elegant and safe solution,” said Jim Tomasulo, Helix’s director of engineering. “We anticipate using drones for this and other purposes.”

Drone inspections of reservoirs, treatment plant

The Otay Water District also is finding drones useful to save money and improve employee safety.

After a two-year study and evaluation period, the district is now using two camera-equipped drones to assist with preliminary inspections of its water facilities in eastern and southern San Diego County, including 40 potable water reservoirs, four recycled water reservoirs, 20 pump stations and a recycled water treatment plant.

Drones Reduce Risk

Countywide, the Water Authority uses drones to monitor rights of way and to survey inaccessible landscapes.

When a drone was used to get images and video of steep terrain on the Second Aqueduct west of Interstate 15 and south of the San Luis Rey River, the images were 10 times higher resolution than stock aerial images. Using the drone also kept staff from being exposed to potentially dangerous conditions.

The Water Authority is also exploring using drones for future surveys and potentially at water transportation, treatment, and storage facilities, where cutting-edge technology is used to save ratepayers money.

Drones are helping the Water Authority monitor rights of way, particularly in areas of rugged terrain.

But the potential of drone use is not limited to visual photography of elevated water tanks and surveying remote areas. Water quality monitoring is another potential application.

Water agencies can use drones with infrared cameras “to monitor water areas remotely at higher spatial resolution than ever before, at low cost and at any time,” Michal Mazur, with Drone Powered Solutions, told Waterworld.com in a recent article about the advances in drone use.